In my last post on this topic, I suggested that there were potentially three groups of maker/dealers involved in flutes that were ostensibly of Dublin manufacture.

One of the many problems facing research in this area is the rarity of such instruments, which makes comparisons quite difficult.

The Dublin Music Trade resource names 18 woodwind makers naming flutes among their wares, who operated in Dublin in from the mid 18th - the mid 19th centuries, and of course there were a few more in Cork and other places outside Dublin. Of these, less than 25 instruments are currently known from only 12 makers, of which 14 are flutes. (Excluding Butler, who being a later maker having a London branch has very many known instruments) Alphabetically they are:

Brown, Butler, Colqhoun, Connor, Cowlan, Dollard, Ellard, Heron, Hussey, Moroney, Neale, Perry, Reilly, Robinson & Bussel, Stokes, Thornton, Voyer, Willis.

To this list I've been able to add two names. Firstly Finnegin (sic) whose single key boxwood flute is stamped CORK, and who may be the same person as the uilleann pipe maker Finnegan recorded from early 19th century Cork. Secondly, a double flageolet stamped C. Toomey Dublin, surfaced very recently at an auction in Switzerland. This Toomey is more normally thought of as an American maker based in Georgetown D.C., and even though it's unlikely that this instrument, in common with many of the ones under consideration here, was actually made in Dublin, it is another Dublin stamped instrument which inspires me to look further into C. Toomey's potential Irish background.

The information I can garner about these makers further confirms the inter-relationships (dynamic) between the three groups that I propose were involved in the Dublin flute making scene in late 18th and early 19th century Dublin;

- Makers of uilleann pipes who also offered flutes.

- Makers of flutes and other woodwinds for the classical trade.

- London makers who made flutes then stamped with the marks of either or both of the previous two groups.

In the last while I've managed to get hold of two very nice examples of flutes made in...or at least stamped...Dublin, and another, which although from a Liverpool address, is from a maker whose Irish origins are undisputed, and who had previously worked from a Dublin address.

The first two are one keyed boxwood and ivory instruments typical of the turn of the 18th/19th centuries

One of these is stamped Colquhoun Dublin, a name listed in the Dublin Music Trade website under several entries. In fact, there were two Colquhouns, Henry and George, who worked in association with several others. ( indeed there was a third, William, who is listed as a musical instrument maker in Cork, but of whom nothing else is known)

This must be the first and only time that I acquired a flute whose maker gets mentioned in a poem the context of which is detailed by Carolan ( see refs below)

Here's the extract from "An Heroic Epistle, from Kitty-Cut-a-Dash to Oroonoko"

Love's mystic pleasures o'er, a minstrel near,

Obsequious waited, to delight the ear

In these degenerate times, a piper named,

The first of Tibecens, tho' little fam'd

His pipes of sable ebony were made,

By Colq'houn, skilful in the Tibian trade;

Rings of contrasting ivory surround

The drones, the tips with burnished brass are bound:

Such tones he from his matchless chanter drew,

When o'er the holes instinctive fingers flew...

Nor was his skill to sleepy airs confin'd

But lively Notes reveal'd a lively mind,

The festive dances, Gods! How he would roar 'em!

BLACK JOKE, BOW-WOW, or PUSH ABOUT THE JORUM

George was active from 1771, but is only listed as a musical instrument maker from 1793. Henry...the two are probably related, but no evidence is offered...is active from 1765 in partnership with a John Voyer, and for two years from 1766 with John Gahagan. Unfortunately we know very little about these early Irish makers, but some of the detail recorded is intriguing. Talking about the Voyer/Colquhoun partnership in the same article, Carolan refers to a letter which appeared in Faulkner's Dublin Journal

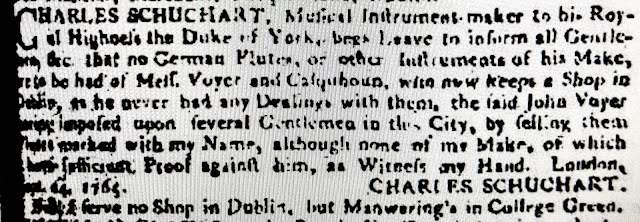

"A letter of September 1765 records a 'Calquhoun' (sic) as having recently set up a music shop in Dublin with John Voyer, and accuses Voyer of passing off counterfeit German flutes there, supposedly made by Charles Schuchart of London."

Which must be the first time that Schuchart was ever accused of making counterfeit flutes!

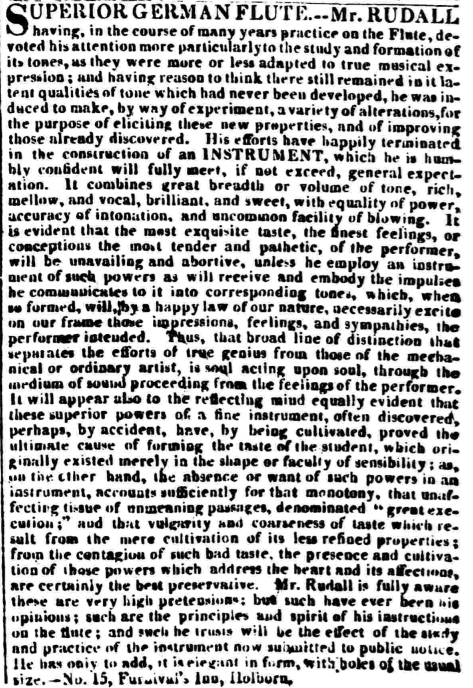

I was intrigued to follow up on that reference, and eventually now that the Covid situation allows visiting the National Library, I managed to get there a couple of weeks ago...and so here is the original...

This appears to be, not a letter, but something in a similar form to other tradesmen's notices, letting people know where certain items are to be had, or in this case, not to be had. The text is quite hard to read, so this is what it says:

Charles Schuchart, Musical Instrument maker to his Royal Highness the Duke of York, begs leave to inform all Gentlemen &c that no German Flutes, or other instruments of his make are to be had of Mesr. Voyer and Calquhoun, who now keeps a shop in Dublin, as he never had any dealings with them, the said John Voyer having? imposed upon several Gentlemen in this City, by selling them flutes marked with my Name, although none of my Make of which I have sufficient proof against him, as witnesss my hand. London Sept. 14 1765.

We serve no shop in Dublin, but Manwerings in College Green.

This snippet is interesting in that it reveals something of the relationship between, makers and dealers, and also of the connections between the London and Dublin markets and musical scenes. It's important to understand some of the political background of the period, in particular the 1801 Act of Union, which dramatically changed the political and commercial relationship between Ireland and England. This post is not the place to do it, but perhaps at some future date a sketch of the basics would be useful.

Following up on references both in the NLI and the DMT sources led to a flute by Colquhoun in Berlin, which I was amazed to discover is a flute in F, low F, which in the rather bizarre official naming system means that the low note, the six-finger note ( this is a one keyed flute) is G. The Berlin Musical Instrument Museum lists this as being by George Colquhoun, and the stamp is identical to that on my Colquhoun. The flute is made of very finely flamed box, with ivory mounts.

I note that the paragraphs above were written in January 2021, and it was at this stage that the Covid crisis was really starting to bite, and it took a long time to make contact with Berlin, and to get access to the images that they had. They asked me not to use the images in a publication which of course I'll comply with.

The second flute came to me in a way which illustrates the wonderfully generous nature of the flute community.

I was poking about on the internet, and came across the website of the Breton flute maker Solen Lesoueff, whom I had known about, as my friend and fellow fluter Aoife Granville has a fine example of her work. There I noted that she had documented a series of old flutes that she had acquired from various sources, and scrolling through that, I was amazed to discover that among them was a one keyed boxwood and ivory flute stamped Hussey, Dublin.

More on the off chance than anything else I wrote to her explaining my interest in, and the research I was undertaking about the Irish made/stamped flutes. I offered to buy the flute if she was willing to sell, or swop for something in my collection that would be of interest to her.

To my great surprise and delight she offered to give me the flute, saying that it's proper home was in Ireland, and so it came into my hands.

The third instrument which increases our knowledge of "Irish" flutes, is an instrument in the Hunterian Museum in Glasgow, which I had the opportunity to visit and study some months ago.

This is an eight keyed flute in ivory and silver, which is stamped J. Reilly Dublin. I believe there is another example of this maker's work, also in ivory in the NMI. but numerous inquiries have failed to get any response from them on this front. Here's the Glasgow instrument.

This flute has several very interesting features, and I can't wait to compare with the Dublin Reilly.

One of the advantages of spending so long in putting together these blog posts is that often some other relevant piece of the puzzle turns up in the interim...and so it happened in this case, and it turns out to be one of the most fascinating pieces so far. This one came to me via Stephen Chambers who had thrown it in as part of another deal, and then couldn't find it. It eventually turned up some months later, having fallen behind a cabinet.

It's a 7 keyed flute ( no long F ) cocus wood and silver, and although in a bad state it still shows some very interesting features.

The flute is stamped...

JUNr

COWLAN

2 WHITE CHAPEL

LIVERPOOL

IMPROVED PATENT

This in itself is new information in that this Jun(ior) Cowlan is presumably the next generation to the Cowlans listed in the NLI

To which of the three groups might these flutes belong? Initially, it seems that the Hussey must surely belong to the group of pipemakers who also offered flutes, while the Colquhoun, while it might potentially belong to the same group, I'm inclined to think, because of the quality of the instrument, that it might very possibly have been made for the classical market. The Reilly is very possibly then, the third group of London made instruments, stamped Dublin. But what of the Cowlan? This I find to be the most intriguing of the instruments and since my last attempt to finish this post I've become aware of quite a lot more information about the Cowlans, and also another example of his work, so I'm thinking that perhaps they deserve a post of their own.

Till the next time....

Refs:

Cutting a Dash: Uilleann Pipes in the 1760s and 1770s. Nicholas Carolan. An Piobaire, Vol 4, no. 35